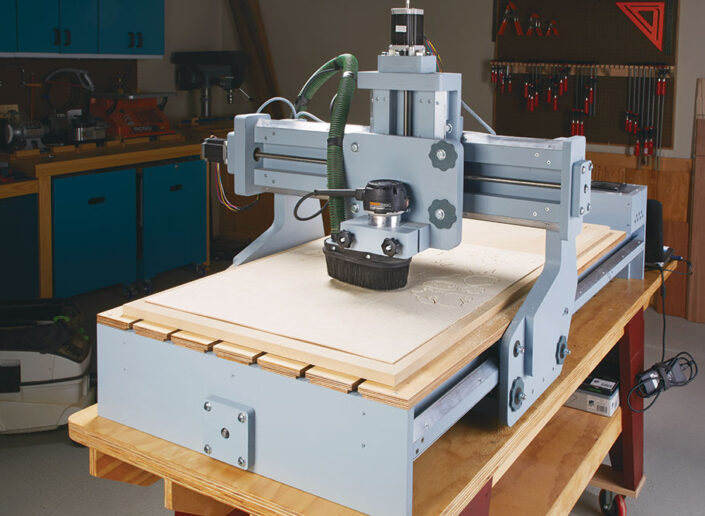

Woodworking is a craft that requires precision and accuracy. Small CNC equipment has revolutionized the way woodworkers are able to achieve these goals. In this article, we will provide tips and best practices for working with small CNC equipment when it comes to woodworking projects.

We will discuss the various components of small CNC equipment, as well as how they can be used in different types of projects. Additionally, we will cover safety precautions and tools necessary for successful operation of small CNC machines.

By following these tips and best practices, you can ensure that your next project is completed accurately and safely while taking advantage of all the benefits provided by modern day technology!

1. Preparation for Working with Small CNC Equipment

Working with small CNC equipment for woodworking requires a great deal of preparation. Before using the machine, it is important to understand its capabilities and limitations to ensure that the desired outcome can be achieved. There are several things you should consider in order to maximize your efficiency when working with a small CNC device.

First, familiarize yourself with the software associated with your specific machine model. This will help you better utilize all its features and settings. Additionally, read any user manuals or instruction guides for further guidance on how best to use the equipments features or troubleshoot any potential problems that may arise during operation.

Next, create 3D models of what you plan to produce on the machine before actually running it; this helps eliminate potential errors as well as saving time while programming and setting up jobs on the CNC device itself. Also consider creating sample pieces prior to beginning production work; doing so allows you to adjust certain parameters if needed and make sure everything runs smoothly throughout each job cycle.

Finally, check all components such as cutting tools and bits regularly for wear or damage – replacing them whenever necessary — in order keep your projects running efficiently without interruption due to faulty parts or tools!

2. Selecting the Right Tools and Materials

Selecting the right tools and materials for small CNC equipment can be a daunting task. Whether youre a seasoned woodworking veteran or just starting out, its important to understand what kind of tools and materials will work best with your machine. With the wide variety of products available on the market today, it can be hard to know where to start. Fortunately, there are some tips that can help guide you in selecting the ideal components for successful projects using small CNC machines.

When choosing which type of wood to use with your small CNC equipment, consider both unprocessed solid lumber as well as manufactured boards like plywood and MDF board. In general, these types of woods tend to provide enough stability when machined that they dont need additional support structures such as clamps or jigs during cutting operations. Additionally, some woods may require specialized tooling for optimal performance; research accordingly before purchasing any material for your project.

The choice between air-cooled and liquid-cooled spindles is an important one when selecting components for small CNC machines. Air cooled spindles are generally more affordable than their liquid cooled counterparts but also generate more noise during operation due to the fan used in cooling them down – this could be an issue depending on where you plan on using your machine! Liquid cooled spindles offer quieter operation at a slightly higher cost; however they often last longer too so may end up being worth the investment over time if frequent use is expected from your machines setup.

Finally, pay close attention when purchasing bits and cutters compatible with smaller sized materials commonly found in woodworking projects like dowels or thin strips – typically 1/8 (3mm) thick or less – since many standard bits have diameters too large to easily accommodate such sizes effectively without experiencing problems like splintering along edges during cuts resulting from too much pressure applied by larger diameter tooling against delicate material surfaces!

3. Operating Your Small CNC Machine Safely

When operating a small CNC machine, safety should be the top priority. It is important to read and understand all manufacturers instructions before using the machine. Additionally, it is recommended to wear protective gear such as goggles, hearing protection, gloves and other clothing when working with a CNC machine. After reading through all of the materials provided by the manufacturer on how to use the machine safely, take some time to familiarize yourself with its basic controls. Make sure you know where your emergency stop button is located in case an unexpected situation arises during operation.

Before starting up any CNC machinery for woodworking tasks always make sure that everything has been set-up correctly; this includes double-checking connections between components and ensuring that there are no loose parts or wires present which could cause accidents or damage expensive equipment. When ready to begin machining operations ensure that any tools used are secure and properly placed so they don’t interfere with moving components then fire up your machine according to manufacturers directions while taking care not to exceed speeds or feed rates specified by them too quickly as this can lead to damaging results from overloading motors and other components of your setup.

Once operational pay attention at all times while running small CNC machines particularly if carrying out complex projects involving multiple cuts because mistakes here can have costly consequences due changes being hard resetting mid cycle without manual intervention so always perform a test run prior engaging in full scale production runs just in case something does go wrong quickly aborting program execution will save both time & money down line!

4. Benefits of Using a Smaller-Scale CNC in Woodworking

Using a smaller-scale CNC in woodworking can provide many benefits over traditional methods. Not only does it create precise cuts with less effort, but it also offers more control and accuracy than manual tools. Additionally, it reduces the time spent on repetitive tasks due to its automated nature and saves money by eliminating the need for expensive equipment.

Furthermore, smaller-scale CNC machines are able to cut complex shapes that would otherwise be difficult or impossible to do manually. Finally, these machines can produce high quality results at a fraction of the cost compared to larger-scale CNCs, as well as be conveniently stored when not in use. In conclusion, investing in a small-scale CNC is an excellent way for any woodworker to upgrade their toolkit without breaking the bank.