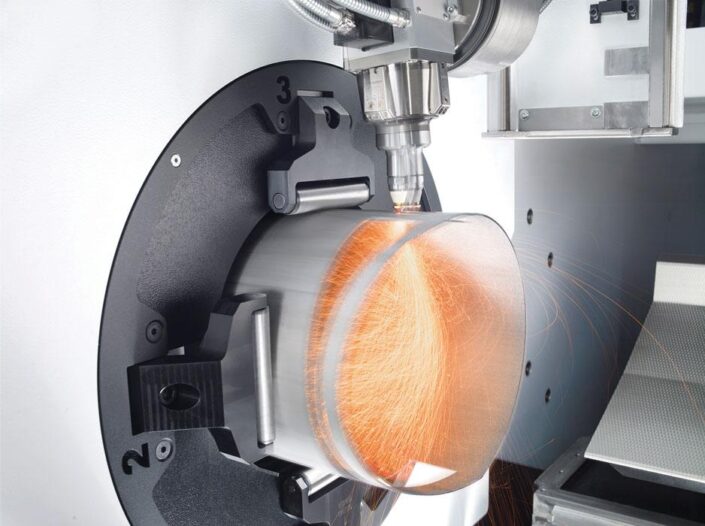

Fiber cutting with lasers is revolutionizing the fabrication of sheet and tube materials. From aerospace to automotive, the ability to cut complex shapes in a fraction of the time it took before has made laser technology an invaluable tool for today’s manufacturers.

But as demand grows for ever-faster and more precise cuts, harnessing the full potential of laser fiber cutting requires understanding its unique capabilities and limitations. This article takes a look at how lasers can be used to precisely cut sheet or tube material with speed and accuracy that was unimaginable just a few years ago.

Introduction to Lasers and Their Uses in Sheet and Tube Fiber Cutting

Lasers are powerful tools in the sheet and tube fiber-cutting industry, enabling faster and more precise cuts than ever before. As a result of their numerous advantages over traditional methods such as sawing or milling, lasers have become increasingly popular with fabricators, technicians, and manufacturers alike.

This article provides an introduction to lasers and their uses in sheet and tube fiber cutting, exploring the basics of how they work as well as some of the benefits they offer. We will further discuss various laser types available on the market today – from CO2 to Nd: YAG – along with key variables you need to consider when choosing one for your specific application. Finally, we’ll provide examples that demonstrate how these versatile machines are being used across multiple industries for a variety of tasks.

Whether it’s slicing through steel sheets or forming intricate shapes out of titanium tubing, there is no doubt that lasers continue to drive innovation within this rapidly evolving field!

Benefits of Using Laser Cutters for Sheet and Tube Fiber Processing

Using laser cutters for sheet and tube fiber processing offers numerous advantages that make it an ideal choice for many businesses. Laser cutting is a much quicker process than traditional methods, resulting in shorter lead times and faster production rates.

It also eliminates the need for tooling, which can be quite expensive when using other types of cutting techniques. Additionally, laser cutters can produce more precise cuts with greater accuracy compared to other forms of cutting tools, making them ideal for complex shapes and intricate designs.

Furthermore, because there’s no contact between the material being cut and the cutter itself during operation, there’s less risk of damage or defects caused by heat or friction while still providing high-quality results quickly. Finally, laser cutters require minimal maintenance due to their low power consumption and overall dependability, helping to reduce operating costs over time. With so many benefits associated with utilizing laser cutters for sheet and tube fiber processing operations, it’s easy to see why they remain such a popular choice amongst businesses looking to maximize efficiency while producing superior quality products consistently.

Understanding the Different Types of Lasers Used in Sheet and Tube Fiber Cutting

When it comes to sheet and tube fiber cutting, lasers are a highly efficient and effective tool. Lasers offer the ability to cut with precision and accuracy due to their tightly focused beam of light.

There are three main types of lasers used in sheet and tube fiber cutting: CO2, YAG (Neodymium-doped Yttrium Aluminum Garnet), and Fiber Lasers. CO2 lasers use a gas mixture of carbon dioxide, nitrogen, helium, or hydrogen as their active medium.

These lasers produce an infrared wavelength that is well absorbed by organic materials like paperboard, wood, plastics, and acrylics; making them ideal for engraving or marking applications on these surfaces. YAG laser systems utilize a solid crystal made from neodymium-doped yttrium aluminum garnet as their active medium which produces an intense beam of light that can be tuned to different wavelengths depending on the application needs.

This makes YAG laser systems suitable for cutting materials such as metals including brass, copper alloys, or stainless steel; uncommonly cut with other laser technologies because of their higher reflectivity towards infrared radiation.

Conclusion

The potential of sheet and tube fiber cutting with lasers is immense. Lasers are a powerful tool that can help create intricate designs out of metal, plastic, or other materials quickly and accurately.

Tube Fiber Cutting, in particular, has become increasingly popular due to its ability to produce products with precise measurements and complex geometric shapes. By taking advantage of the luster produced by laser beams, businesses have been able to reduce production costs while still delivering high-quality goods on time.

With continued advances in laser technology, it’s likely we will see more applications for sheet and tube fiber cutting in the future.