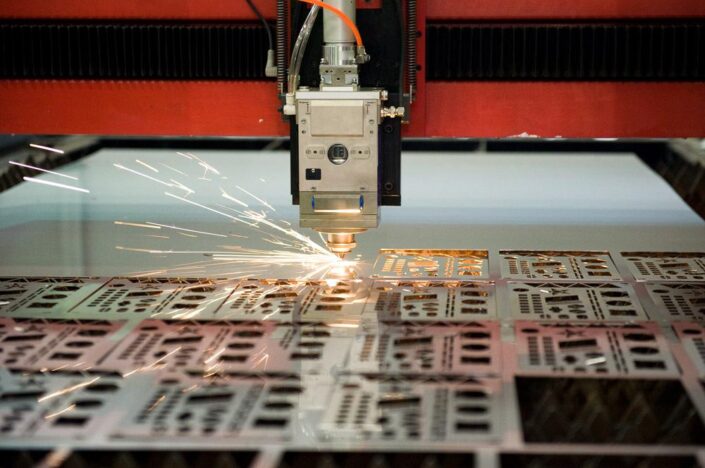

In recent years, laser cutting technology has revolutionized the industry. From commercial manufacturing to home woodworking projects, laser cutters are quickly becoming an essential tool for achieving precise results that were otherwise impossible.

By using a concentrated beam of light to precisely cut and engrave materials like metal, plastic, paper, and wood with extreme accuracy and detail, laser cutters allow craftsmen and professionals alike to create complex designs faster than ever before.

The possibilities offered by this revolutionary technology have opened up new opportunities in many industries from jewelry design to automotive production.

In this article, we explore how lasers are changing the way we work by taking advantage of their unique capabilities – from precision cuts at high speeds to intricate designs with remarkable detail – all made possible through modern laser cutting technologies.

Different Types of Lasers Used For Cutting

When it comes to cutting, different materials require different types of lasers for the best results. CO2 lasers are widely used and have been known to cut up to 6 inches thick in certain metals like steel or aluminum without leaving any burrs or slag behind.

Fiber Lasers generate a high-intensity beam that can instantly melt metal surfaces due to its concentrated power output. Excimer Lasers combine ultraviolet radiation with noble gas mixtures so they can perform delicate ablative processes on sensitive substrates without causing damage from thermal shockwaves caused by traditional laser systems operating at much higher power levels.

Diode-Pumped Solid State (DPSS) Lasers offer an efficient alternative when working with soft materials such as wood, plastic, fabric, and paper while also providing precise engraving capabilities for creating intricate designs and markings on hard surfaces like metal or ceramics.

All of these technologies offer their benefits depending on what type of material is being processed, making them invaluable tools in today’s manufacturing industry!

Advantages and Disadvantages of Laser Cutters

The advantages of laser cutting are unquestionable. They offer speed and accuracy, minimal setup time, no risk of parts slipping or breaking during cutting operations, smoother edges than those produced by other cutting methods, and reduced costs associated with materials and labor hours needed for production processes.

However, the drawbacks to using laser cutters must be considered before investing in one for business needs. They can be quite expensive up front and require a large amount of energy when running which increases electricity bills over time.

In addition, certain materials such as reflective surfaces may not work well due to reflections generated from light used inside machines causing damage if not handled properly. Finally, fumes created during operation can create uncomfortable working conditions if proper ventilation isn’t provided within the workspace environment.

By taking all these aspects into consideration businesses will be able to make an informed decision when deciding whether or not a laser cutting is right for them.

How Laser Cutters are Reducing Costs in Manufacturing Industries

Laser cutters are revolutionizing the manufacturing industry by reducing costs and increasing efficiency. By providing faster and more accurate cuts than traditional blades, laser cutters eliminate manual labor hours while still producing high-quality products with great precision.

Furthermore, because lasers require less energy than blade machinery they are also much cheaper to operate over time – resulting in lower production costs overall.

On top of reducing costs associated with materials and labor hours needed for production processes that involve a lot of cuts or details; laser cutting also provides a higher quality finished product due to their uniformity – saving businesses even more money in the long run through reduced replacement costs caused by faulty products or components failing prematurely over time from wear-and-tear related issues often seen in traditionally machined parts/products.

In conclusion, it is clear why many manufacturing industries are turning towards laser technologies: improved accuracy leads directly to better results along with major savings due to both upfront costs as well as long-term maintenance fees associated with traditional methods – making them one obvious choice when it comes to optimizing profit margins within this sector!

Future Trends in the Use of Laser Cutters

As laser cutting becomes more accessible and advanced, businesses across all industries have the potential to benefit from its technology. In the future, it is expected that laser cutting will continue to improve in accuracy and speed as well as decrease costs.

This could lead to increased customization options for mass-produced items at a cheaper cost than ever before, further revolutionizing manufacturing processes. Additionally, software advancements will make it easier for designers to create intricate designs without needing additional equipment or personnel onsite which would save time and money while still providing customers with higher quality products overall.

Finally, energy efficiency continues to be another trend that looks set to stay; lasers require very little power compared with many other machines so businesses can save money on electricity bills while also reducing emissions released into our atmosphere – something everyone should be striving towards!

Conclusion

The technology of laser cutting has revolutionized the industry, providing high accuracy and speed to cut through a variety of materials. Thunder Laser cutter stands out among the rest by offering an impressive set of features that allows for precise and accurate cuts with minimal waste. With its ability to process even complex designs quickly and accurately, laser cutters are becoming increasingly essential for businesses in all industries.

From small shops to large manufacturing facilities, they offer efficient solutions that allow businesses to stay competitive in ttoday’smarket while still maintaining their quality standards. In short, laser cutters are changing the industry by enabling faster production times and higher levels of precision than ever before.