Computer simulation has become an essential asset in the modern design of steel castings. By providing a virtual environment for testing and tweaking, simulations have enabled engineers to explore innovative solutions and improve the efficiency of their designs. Through computer simulation, engineers can gain insights into the behavior of metal under different conditions, allowing them to identify potential problems before they arise in physical models.

In addition, simulations allow designers to optimize casting geometry without spending time and resources on costly prototypes or tests that may not be successful. This article will examine how computer simulation is transforming the process of steel casting design and explain some of the benefits it offers today’s engineers.

Improved Efficiency and Cost Savings

Computer simulation is one of the most important tools in steel casting design, allowing for improved efficiency and cost savings. By leveraging computer simulations to evaluate designs before committing to a physical prototype, companies can reduce costs associated with traditional trial-and-error methods.

Computer simulation also reduces time spent on iterations for perfecting casting designs, as it allows designers to quickly make changes and test new ideas without having to produce multiple prototypes. This makes computer simulations more efficient and cost-effective compared to conventional design processes.

Additionally, by using computer simulations companies can identify potential flaws or problems early in the process which helps them prevent costly errors from occurring during production. In sum, incorporating computer simulations into steel casting design provides numerous benefits such as improved efficiency, greater accuracy, and cost savings over traditional design approaches.

Faster Design Iterations and Improved Accuracy

Computer simulation offers steel casting design engineers the ability to quickly and efficiently evaluate various designs, allowing for faster design iterations and improved accuracy. By utilizing computer simulations, designers can identify potential problems with a given design before it is put into production, saving time and money in the long run.

The use of computer simulation also eliminates guesswork when it comes to predicting how a particular design will perform under certain conditions or in specific environments. This allows engineers to make more informed decisions about the best way forward for their projects.

Additionally, computer simulations can be used to test different materials, ensuring that only those which meet all required standards are used in final products. Computer simulations offer an invaluable tool for streamlining processes within steel casting design engineering operations while at the same time providing increased accuracy over traditional methods of evaluation and analysis.

Reduced Risk in Steel Casting Production

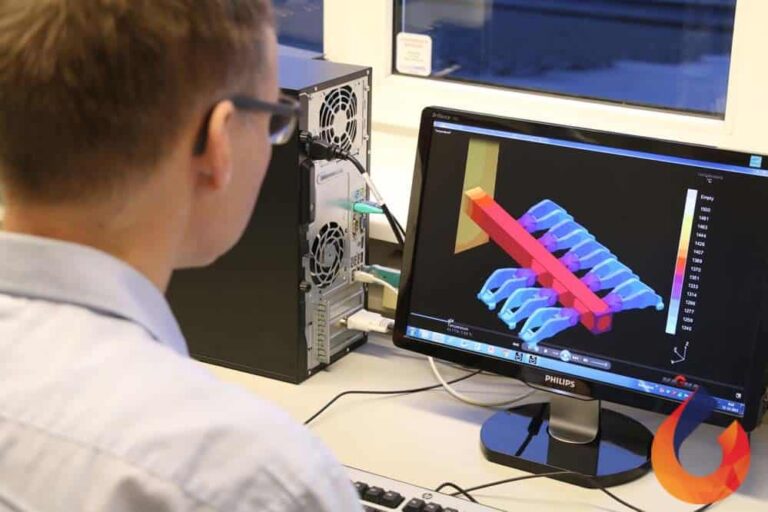

Computer simulation has revolutionized steel casting design, allowing for reduced risk in production. Designers can take advantage of the high-fidelity simulations available today to analyze their models and make informed decisions about their designs before committing any resources to the manufacturing process.

Computer simulations give designers complete control over every variable in their model, from temperatures and pressure levels during pouring to metal shrinkage as it cools down. This enables them to create more efficient and reliable designs while mitigating potential risks associated with traditional methods of production.

Furthermore, computer simulation technologies can provide accurate predictions on cooling times and other important parameters which further reduce the risks inherent in steel casting production. With these powerful tools at hand, engineers can confidently move ahead with safe and successful projects that will lead to greater efficiency in industrial applications across many industries.

Enhanced Ability to Test Multiple Variables

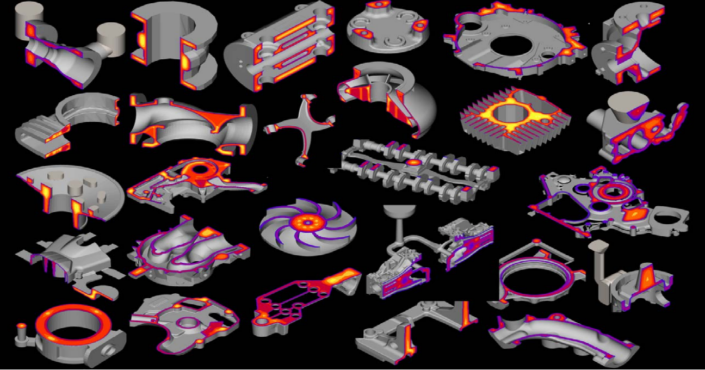

Computer simulation in steel casting design offers an enhanced ability to test multiple variables quickly and easily. This powerful tool can simulate the entire process of a specific casting job, allowing engineers to explore different designs and materials while predicting results with higher levels of accuracy.

With this technology, manufacturers can identify problems before production begins, saving time and money by avoiding costly errors. Computer simulation also helps reduce environmental impacts from unnecessary experimentation with actual products.

The advantages are clear: testing many possible solutions within a virtual environment allows for greater precision when it comes to optimizing product performance without compromising safety or quality standards.