As the world continues to become more aware of the environmental issues facing us, businesses and individuals alike need to understand their role in reducing waste and protecting our environment. PCB manufacturing and disposal present unique challenges when considering environmental concerns because of both the materials used in production as well as disposal protocols.

This article will explore the impacts that these processes have on our planet, from material sourcing to end-of-life considerations, with a focus on reducing negative environmental outcomes while maintaining efficient operations.

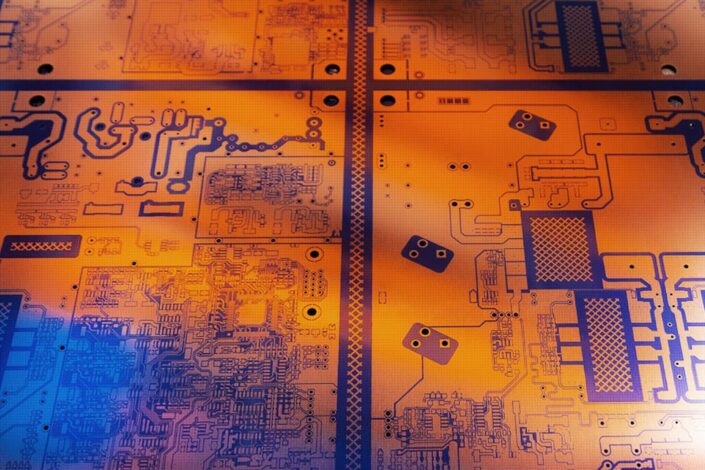

Environmental Considerations in PCB Manufacturing

When it comes to environmental considerations in PCB manufacturing and disposal, several factors must be taken into account. Firstly, the choice of materials used in production has a direct impact on the environment – hazardous substances like lead should be avoided where possible.

Secondly, proper waste management and recycling practices must be implemented for both unused components as well as any post-production leftover materials. In addition, safe handling procedures need to be established when dealing with dangerous chemicals or vapors emitted during the manufacturing process.

Finally, special attention should also be given to emissions from equipment such as soldering tools or laser cutters which can contain toxic particles if not properly filtered or vented away from personnel areas. By considering all these aspects, manufacturers will help ensure their PCBs are produced in an environmentally friendly way while also helping protect those involved in its fabrication process.

Environmental Considerations in PCB Disposal

When it comes to the environmental considerations of PCB disposal, proper handling is essential. Any PCBs being disposed of must be handled with consideration for their potential impacts on the environment.

All components must be properly segregated before disposal and should never be mixed with other materials or waste streams. The components need to be safely contained to prevent contamination of air, soil, and water resources from hazardous chemicals such as heavy metals or lead solder residues. In addition, PCBs containing valuable metals may also require special recycling methods to ensure that these materials are not wasted but recovered and reused responsibly.

Furthermore, when disposing of large quantities of printed circuit boards it is important to use an appropriate method that takes into account local regulations regarding the safe transportation and disposal of hazardous material. Finally, anyone involved in disposing of electronic waste should have access to training on how best to manage this process safely and effectively while minimizing its impact on the environment.

Conclusion

The PCB manufacturing and disposal process has a significant environmental impact, from the chemicals used in production to the waste generated through disposal. Businesses need to consider these impacts when designing or procuring their PCBs, as well as managing their manufacture and disposal.

By taking proactive steps such as using recycled materials or responsibly disposing of obsolete products, companies can help reduce their environmental footprint while still achieving quality results in PCB manufacturing.