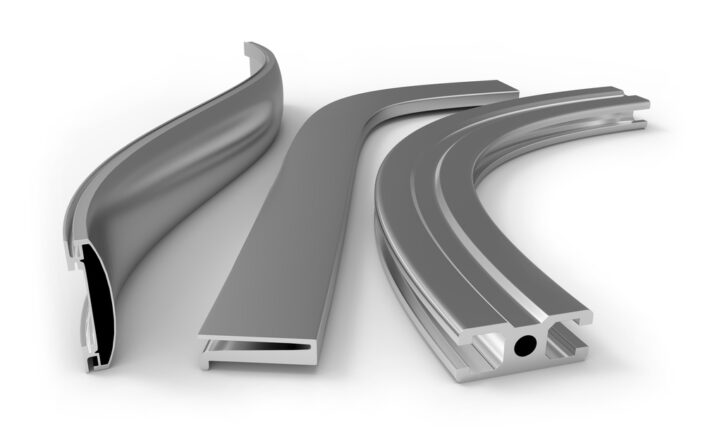

Aluminum extrusions are an essential part of many industries, from aerospace to electronics. These lightweight yet strong components have been used for decades in a variety of applications.

From aircraft wings and engine parts to circuit boards and satellite dishes, aluminum extrusions bring strength, durability, and versatility to the table. In this article, we will explore the various ways that aluminum extrusions can be used across multiple industries including aerospace, automotive, electrical, and more.

Well also look at their advantages over other materials and how they can help improve efficiency in both large-scale industrial projects as well as smaller consumer products. Finally, will discuss some of the potential challenges associated with using aluminum extrusions in certain applications.

So get ready for a deep dive into one of today’s most versatile materials!

Aerospace Industry Applications of Aluminum Extrusions

The aerospace industry has been an early adopter of aluminum extrusions due to their lightweight yet strong characteristics. Aluminum extrusions are used in the construction of aircraft, space vehicles, and satellites as they provide stability while reducing overall weight.

They are also employed for application-specific uses such as airframes, wings, fuselages, and landing gear components. In addition to its lightweight properties, aluminum is resistant to corrosion which makes it ideal for use in the aerospace industry where performance must be maintained consistently over long periods.

The machinability of aluminum extrusions makes them easier to fabricate into complex shapes which can then be used in a variety of applications within the aerospace sector including structural components, engine housings, and thermal protection systems. Finally, aluminum’s recyclable nature makes it an attractive material choice when considering environmental factors associated with manufacturing practices.

Automotive Industry Applications of Aluminum Extrusions

The automotive industry has long been at the forefront of innovation in aluminum extrusion applications. Aluminum extrusions are used extensively in cars, vans, buses, and other vehicles for a variety of purposes.

From body panels to chassis components, wheels, and suspension systems; aluminum extrusions are being utilized more than ever before. By using lighter-weight materials such as aluminum instead of heavier steel components, automakers can reduce vehicle weight without sacrificing strength or performance.

This helps improve fuel efficiency while maintaining durability and safety standards for their vehicles. Additionally, due to its malleable nature and versatility when it comes to shape design; many automotive manufacturers favor aluminum over other metals when creating custom parts for their products.

The use of custom-designed extrusions also allows them greater flexibility with the overall design aesthetic they wish to achieve with their vehicles.

Electronics Industry Applications of Aluminum Extrusions

The electronics industry has been using aluminum extrusions for a variety of applications. The material is ideal for use in this sector due to its low weight, excellent machinability, and electrical conductivity.

Extrusions are available in a wide range of sizes, shapes, and alloy types that make them suitable for many different needs in the electronics manufacturing process. One example would be the use of extruded heat sinks as part of thermal management solutions within computer systems or other complex technological components.

They can also be used as frames and housings for circuit boards, providing structural support while ensuring efficient cooling capabilities at the same time. Furthermore, aluminum extrusions can provide reliable shielding from electromagnetic interference (EMI) which is essential when it comes to electronic devices containing sensitive data or circuitry. In addition, precision tolerances are attained with extrusion techniques meaning intricate parts can be accurately produced without compromising on quality or performance standards.

All these features have helped make aluminum extrusions an indispensable tool within this industry over the years

Conclusion

Aluminum extrusions have been used for decades in the aerospace and electronics industries. As technology advances, however, aluminum extrusion has become increasingly popular in a wide range of other industries as well.

Aluminum is lightweight yet strong enough to meet the needs of many applications such as automotive parts, building materials, and medical equipment. Its malleability makes it ideal for producing intricate shapes with precision and accuracy at a low cost.

Large aluminum tubes are also becoming more common due to their ability to withstand heavy loads while maintaining structural integrity over time. In conclusion, aluminum extrusions offer a versatile solution that can be applied across multiple industrial sectors – from aerospace to electronics – making them an invaluable resource for businesses today.