The environment is a precious resource, and we must maintain its health and sustainability. In the world of PCB manufacturing, sustainable practices are crucial to reducing environmental impact.

From sourcing materials to disposing of hazardous waste, there are numerous steps in ensuring a greener approach to production. This article will explore the importance of using sustainable practices when creating printed circuit boards and other associated products.

It will also provide insight into how these methods can help reduce overall energy consumption while still maintaining high-quality output standards. By examining the current state of PCB manufacturing and what steps need to be taken for greater sustainability, this article will show how businesses can make changes now that will have lasting effects on our environment for generations to come.

Introduction to Sustainable PCB Manufacturing Practices

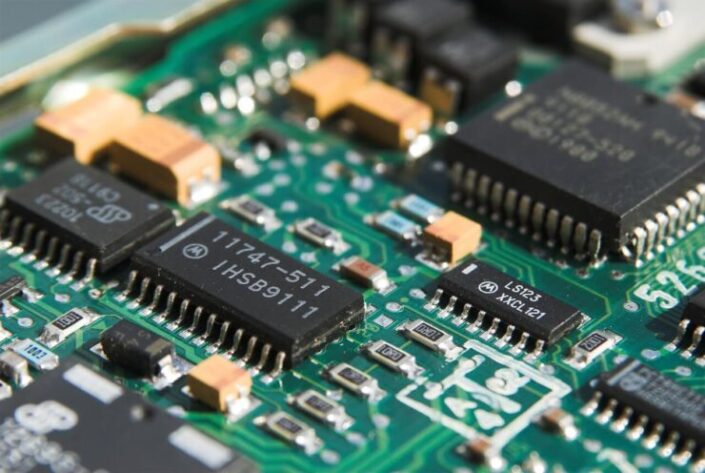

Introducing sustainable practices in PCB manufacturing is an important step in reducing the environmental impact of hazardous materials and processes. There are a variety of ways that manufacturers can improve their operations and reduce waste, from using recycled materials to introducing digital assembly lines with automated components.

Additionally, manufacturers must ensure they are compliant with regulatory standards for emissions and energy efficiency. By exploring the various methods available for making production more efficient and eco-friendly, companies can make a positive contribution to global sustainability efforts while still maximizing productivity.

In this article, we will discuss the main strategies used by leading PCB manufacturers that have enabled them to become leaders in green technology and innovation.

Benefits of Implementing Sustainable Production Methods in PCB Manufacturing

The implementation of sustainable production methods in PCB manufacturing can have several beneficial effects, both for the environment and the industry itself. The use of renewable energy sources, such as wind and solar power, can reduce emissions from factories and mitigate climate change.

This can also lower energy costs for manufacturers who take advantage of these green energies. Additionally, practices that promote the recycling or reuse of materials allow manufacturers to reduce their waste output while preserving resources.

A more efficient approach to producing PCBs may even lead to shorter production times and cost savings over time. Finally, adopting sustainable methods reduces a company’s carbon footprint and establishes them as an environmentally responsible producer which is key in today’s increasingly competitive market landscape. All these benefits provide compelling reasons for PCB manufacturers to adopt sustainable production practices for the future success and sustainability of their businesses.

Environmental Impact of Unsustainable PCB Manufacturing Processes

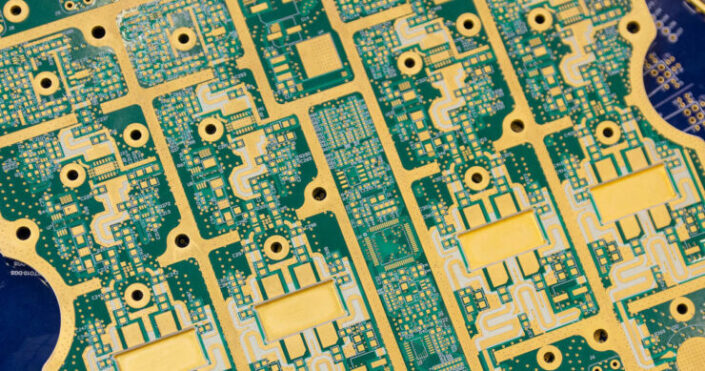

The environmental impact of unsustainable PCB manufacturing processes cannot be overstated. Unsustainable practices can lead to the release of dangerous toxins, such as heavy metals and hazardous gases, into the atmosphere.

In addition, improper disposal of PCB byproducts can contaminate soil and water sources in surrounding communities. This can cause a range of health issues for residents exposed to these contaminants.

Furthermore, energy consumption associated with unsustainable production methods is an additional concern due to its contribution to climate change. As a result, more sustainable practices must be implemented for PCB manufacturers to reduce their environmental footprint and protect public health.

Strategies for Improving the Sustainability of PCB Manufacturing Operations

The use of sustainable practices in PCB manufacturing is increasingly important for environmental preservation. Many strategies are available to help improve the sustainability of operations, such as reducing energy consumption and waste production.

For instance, one option is to assess current processes and identify areas where greater efficiency can be achieved. This may involve transitioning from outdated equipment to more modern technology that consumes less energy and produces fewer emissions.

Additionally, implementing a lean manufacturing system can lead to improved resource utilization resulting in reduced material costs and decreased waste output. Finally, emphasizing reuse or reconditioning of parts rather than disposal will also contribute towards increased sustainability of PCB manufacturing operations.

By taking advantage of these strategies, manufacturers can play an integral role in preserving our environment while still maintaining a successful business model.

Conclusion

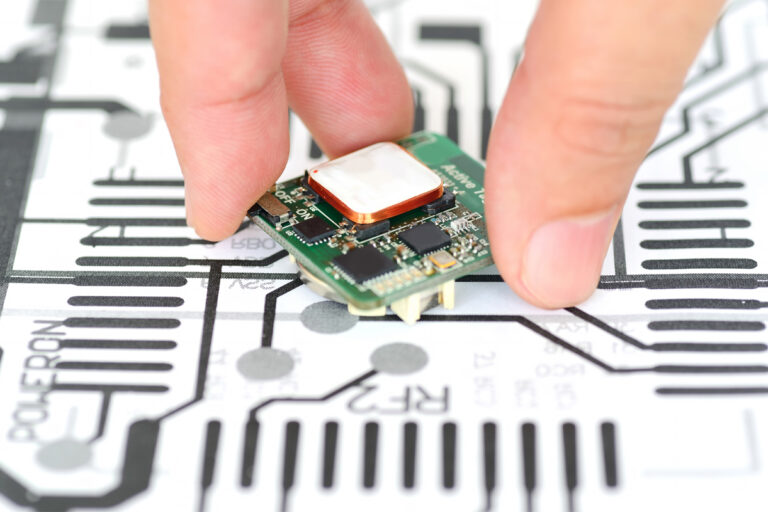

The use of Enepig PCB technology is an example of a sustainable practice that has been adopted by many in the field of PCB manufacturing. It greatly reduces environmental impact by reducing waste and supporting recycling initiatives.

This technology helps to eliminate hazardous materials from entering our environment, as well as reducing energy consumption required for production. By utilizing these practices, PCB manufacturers can create products that are both cost-effective and environmentally friendly at the same time.

Sustainable practices such as Enepig technology play an important role in helping reduce the negative effects on our planet while still providing high-quality electronics for consumers around the world.